PROJECTS

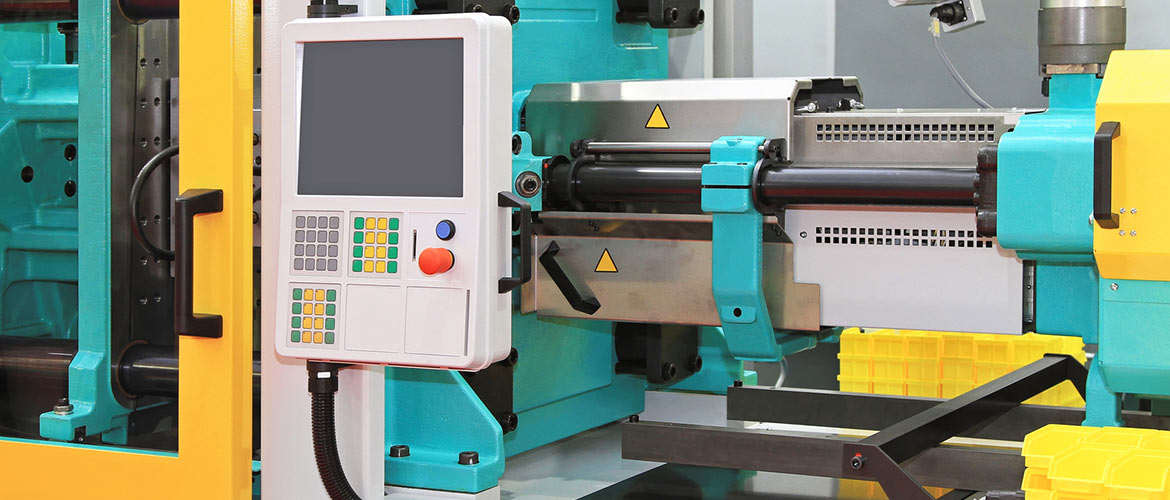

PLASTICS MACHINERY ENGINEERING

The introduction of an offer configurator is often a chance to put products and their internal and external variance to the test at the same time. On the one hand, application parameters on the customer or usage side can often be considerably reduced. On the other, there is substantial potential in integrating offer configuration and order processing with customer order and parts lists configuration in the ERP system plus the CAD-related mapping of ETO processes.

Client: Plastics machinery and plant engineering company > 1,000 employees

Branch: Plastics machinery engineering

Topic: Offer configuration, cutting production costs, product modularisation, classification

Situation: Order processing was time-consuming and throughput times were too long. The offer texts, or rather the machine versions, did not always match the technical state of the art and there were certainly several internal solutions for identical briefs in the marketplace. Offers frequently had the personal touch of the respective sales or design team member, which was reflected in the machine features, pricing or details in CAD, including parts lists management.

Brief:

- Survey of product logic together with sales, project planning and design

- Throwing a critical light on products to be configured with respect to modularity, configurability and dependency in terms of both 3D CAD (Pro/Engineer) and customer order/ERP (SAP)

- Setting up and introducing a uniform offer configurator (camos) for the complete range of products

- Mapping the logic in the configurator together with parallel modularisation and streamlining of the product range

Result:

- Documentation for the product logic used by certain staff, including the knowledge of relationships necessary for product configuration

- Deriving the product/object structure, including the knowledge of relationships plus the class system, including features structure/features/values/value ranges, etc.

- Drastic reduction in the relevant application parameters to just a few parameters for sales

- Revised, modularised and configurable product structures

- Setting up the offer configurator right up to its productive use in sales

- Permanent, substantial decrease in offer workloads and throughput times for compiling offers

- Production costs transparency from offers to historic costing in the ERP system